2020/11/13 15:06:12 人气(1517)

|

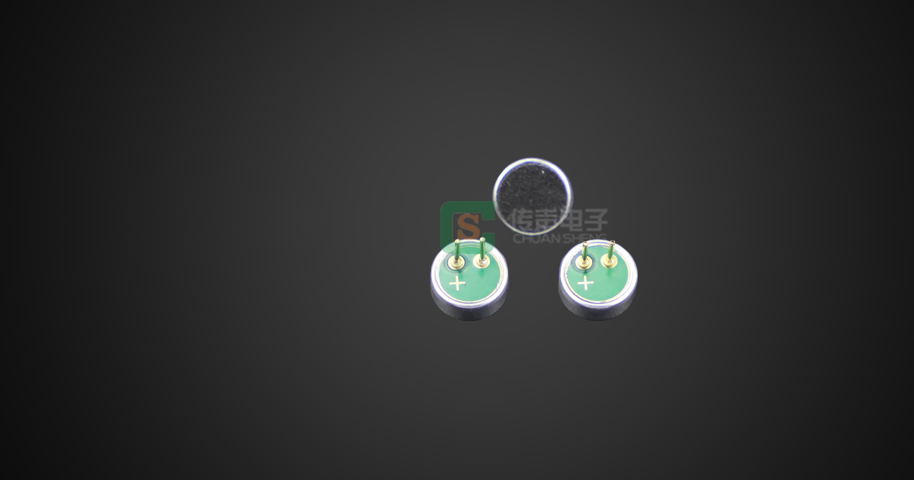

1.SCOPE 范围 | This specification shall be applied to electret condenser microphone(ECM) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2.MODEL NO. 产品型号 | H6022P001A-58DB | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3.ELECTRICAL CHARACTERISTICS 电气特性 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Temp. 环境温度 | 20 ± 2℃ | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Room Humidity 相对湿度 | 65 ± 5﹪ | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4.MEASUREMENT CIRCUIT 测试电路 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

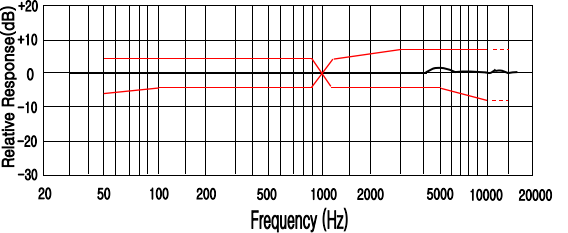

5. TYPICAL FREQUENCY RESPONSE CURVE (FAR FIELD) 频响曲线  |

6.DIMENSIONAL DRAWING 外形图 |

7.RELIABILITY TEST 可靠性测试 | ||

7.1 VIBRATION TEST 振动测试 | 1 minute frequency from 10Hz to 55Hz, amplitude 1.52mm, the vibration in three directions test 2 hours, the sensitivity deviation range of ± 3dB | |

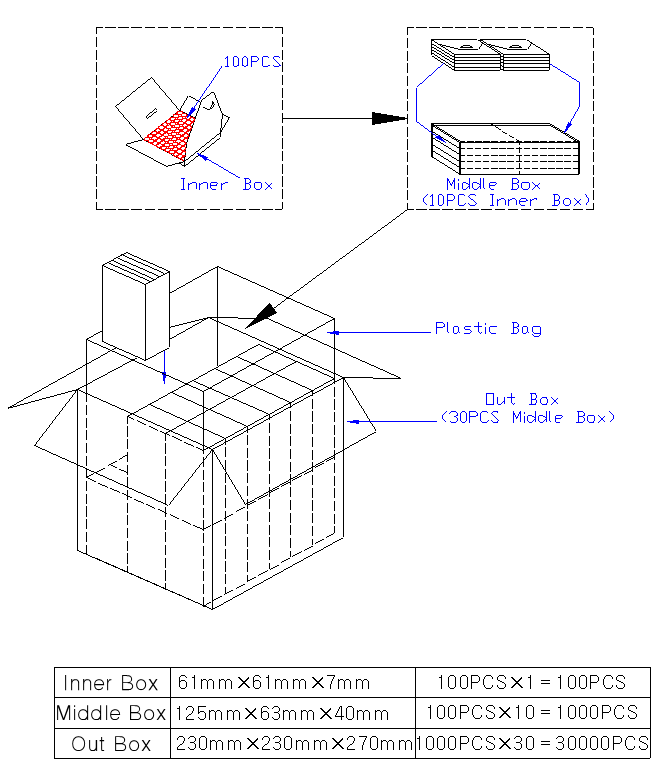

7.2 DROP TEST 跌落测试 | Three directions with the regular packaging of free fall from 1 meter at the concrete floor, the sensitivity range of ± 3dB deviation from the | |

7.3 TEMPERATURE TEST 温度测试 | -After exposure at 70℃ for 72 hours ,sensitivity to be within ±3dB from initial sensitivity | |

7.4 HUMIDITY TEST 湿度测试 | After exposure at 40℃ and 90﹪ relative humidity for 72 hours ,sensitivity to be within ±3dB from initial sensitivity | |

| 7.5 TESTCONDITION 测试条件 | StandardTestCondition: a)Temperature:+15℃~+35℃ b)Humidity:45%-75% c)Pressure:86 kPa -106kPa | |

8.TEMPERATURE CONDITIONS 温度条件 | ||

8.1 STORAGE TEMPERATURE 贮存温度: | -20℃ ~ +70℃ | |

8.2 OPERATING TEMPERATURE 操作温度: | -20℃ ~ +70℃ | |

9.MEASUREMENT SYSTEM 测量系统 |

10.REGARDING THE SOLDERING OPERATION 焊接注意事项 |

1 -Recommend to use 15W ~ 35W ceramic soldering iron and apply 330±20℃temperature range |

2 -Soldering should be accomplished within 2 seconds at each terminal so as not to be overheated. |

3 -ECM shall be soldered fixed on the metal block(heat sink)which has the higher radiation effects. Heat sink shall contact with each of ECM. |

4 -The pin hole soldering shall be avoided. |

5 -E.C.M may easily destroyed by the static electricity,and the countermeasure for eliminating the static electricity(the ground for soldering copper,for worktable and for human body)shall be executed. |

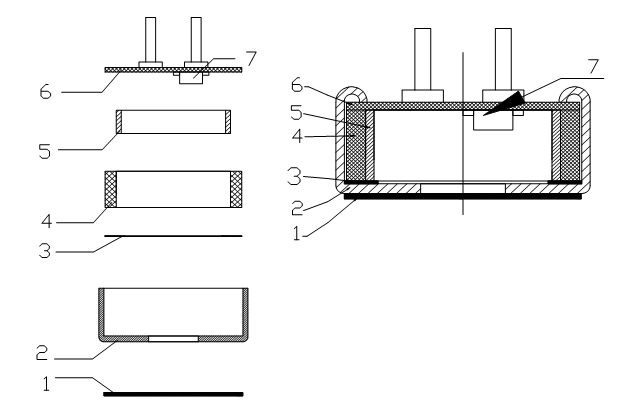

No. 序号 | Part name 部件名称 |

1 | 防水网 FELT |

2 | 外壳 Case |

3 | 垫片 Spacer |

4 | 塑环 Housping Chamber |

5 | 振膜 Diaphragm |

6 | 线路板 P.C.B |

7 | 管芯 FET |

全国统一服务热线

专业客服即时为您解疑答惑