| 1.适用范围:Seope | 本规格书适用于驻极体式电容传声器 This spccification applies electret condenser microphone(E.C.M) | ||||||||||||

| 2.型号: Model No. | H6050P002A | ||||||||||||

| 3.使用条件:Operation Condition | |||||||||||||

| 3.1 环境温度 Temperature | -25~+70℃ | ||||||||||||

| 3.2 相对湿度 Rel.Humidity | 35%~85%RH | ||||||||||||

| 3.3 大气压力 Pressure | 86~106Kpa | ||||||||||||

| 3.4 环境噪声 Environmental Noise | 最大(Maximum):36dB | ||||||||||||

| 3.5 工作电压范围 Operation Voltage | 1~10VDC | ||||||||||||

| 4.电性能 Electrical Characteristics | |||||||||||||

| 4.1 基准工作电压 StandardOperation Voltage | 3.0VDC | ||||||||||||

| 4.2 阻抗 Impedance | 最大(Maximum):2.2KΩ | ||||||||||||

| 4.3 消耗电流 Current Consumption | 最大(Maximum):0.5mA | ||||||||||||

| 4.4 灵敏度 Sensitivity | -60dB±2dB Vs=3.0V R1=2.2KΩ (0dB=1V/Pa,1KHZ) | ||||||||||||

| 4.5 指向性 Directivity | 全指向性(Omni-directional) | ||||||||||||

| 4.6 信噪比 S/N Ration | 最小(Minimum):58dB | ||||||||||||

| 4.7 测试环境温度 Test Temperature 测试环境湿度 Rel.Humidity | 20℃±2℃ 45%~65%RH | ||||||||||||

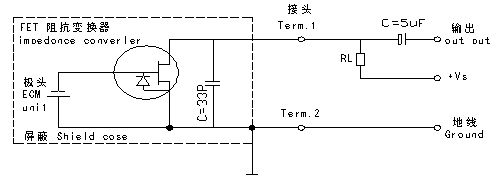

| 4.8 测试电路图 Schematic Diagram Vs=3.0V ; R1=2.2KΩ; C=5uF |  | ||||||||||||

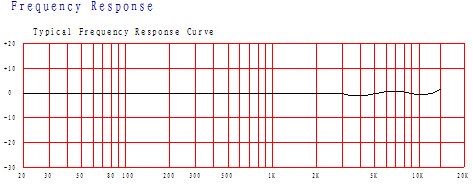

| 4.9 频率响应曲 Frequency Response |  | ||||||||||||

| 5.机械性能 Mechanical Characteristics | |||||||||||||

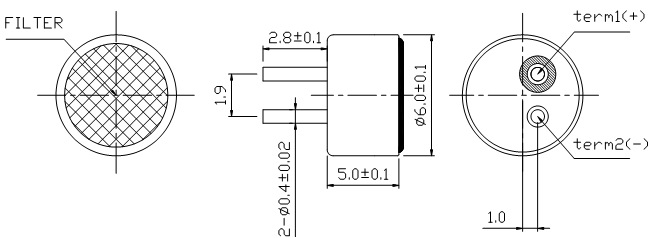

| 5.1 尺寸 Dimension | Φ6.0±0.1×5.0±0.1 | ||||||||||||

| 5.2 重量 Mass | ≤0.3g | ||||||||||||

5.3 外型图 Dimensional Drawing | |||||||||||||

| 6.可靠性试验 Reliability Tests 在下列试验完成后,置于温度为20℃,相对湿度为65%的环境中恢复2小时后进行测试,灵敏度与初始 灵敏度相差在±3dB以内。 The sensitivity to be within ±3dB of initial sensitivity affer 2 hours conditioning at 20℃ | |||||||||||||

| 6.1 震动试验 Vibration Test | 振幅 (Amplitude): 1.52mm 持续范围 (Duration): 1minute 频率范围 (Frequency range): 10Hz~55Hz 3个方向,各2小时 2 hours in each of 3 axes | ||||||||||||

| 6.2 跌落试验 Drop test | 不带包装的跌落到水泥地上 (Drop a unit unpacked onto a board) 高度 (Height) 1m 次数 (Cycle) 6(1 each plane) | ||||||||||||

| 6.3 高温试验 Low temperature Test | 温度 (temperature): +70℃ 放置时间 (Duration): 200hours | ||||||||||||

| 6.4 低温试验 Low temperature Test | 温度 (temperature): -20℃ 放置时间 (Duration): 200hours | ||||||||||||

| 6.5 湿度试验 Statical Humidity Test | 温度 (temperature): +60℃ 相对湿度 (Relative humidity) 90~95% 放置时间 (Duration): 200hours | ||||||||||||

| 6.6温度循环试验 Temperature Cycle Test | -25℃←→20℃←→70℃←→20℃ 5次 (30m) (10m) (30m) (10m) 5cycles | ||||||||||||

| 6.7 温度聚变试验 Temperature Change Test | 低温 (Low temperature) -40℃ 高温 (Low temperature) +85℃ 转化时间 (Changeover time) 30min 放置时间 (Duration) 60min 次数 (Cycle) 32 | ||||||||||||

| 6.8 冲击试验 Shocks | 脉冲波形 Pulse Shape 正弦半波 Half Sinusoidal 脉冲宽度 Pulse Duration 11ms 加速度 Acceleration 150m/s2 冲击次数 Number of Jolts 3个方向,各10次 10 in each of 3 axes | ||||||||||||

| 6.9 静电试验 ESD Test | 在两次无杂质的静电释放暴露中放电.(接触:±8Kv,空气:±15Kv)麦克风在10次暴露后无干扰. The microphone under test be discharged between each ESD exposure without ground.(contact::±8Kv,air:±15Kv)There is no interference in operation after 10 times exposure. | ||||||||||||

| 7.注意事项 Cautions | |||||||||||||

| 7.1 焊接型传声器的焊接,请使用20W-30W的小型电烙铁. The soldering copper of smaller type of less 20W shall be applied. | |||||||||||||

| 7.2 焊接时铜箔表面温度应低于350℃. The temperaure of the working suface of the soldering copper shall be below 350℃. | |||||||||||||

| 7.3 应把驻极体传声器固定在散热良好的装置台上进行焊接. E.C.M shall be soldered fixed on the metal block (heat sink) which has the higher Radiation effects heat sink shall contact with each of E.C.M. | |||||||||||||

| 7.4每个焊点的焊接时间应在1~2秒之内. The soldering time for each terminal shall be 1~2 sec. | |||||||||||||

| 7.5 焊接后,各焊点不应出现沙眼现象. The pin hole soldering shall be avoided. | |||||||||||||

| 7.6 驻极体传声器容易受静电破坏,应采取防静电措施(焊接器具,工作台,操作人员人体应接地) E.C.M may easily destroyed by the static electricity and the countermeasure for eliminating The staticelectricity (the ground for soldering copper for worktable and for human body) shall be executed. | |||||||||||||

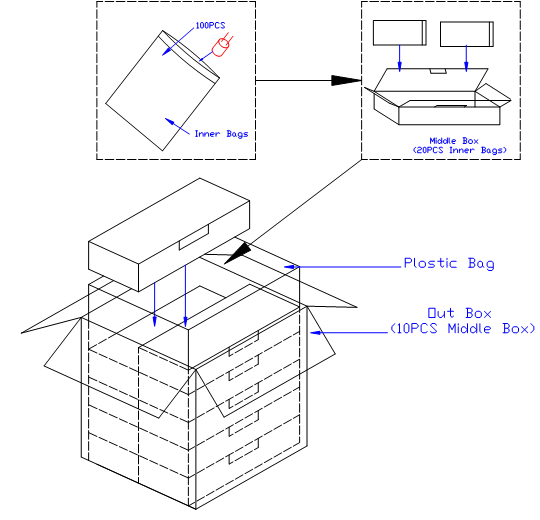

8.包装规格(Packing Specificatons)

| |||||||||||||

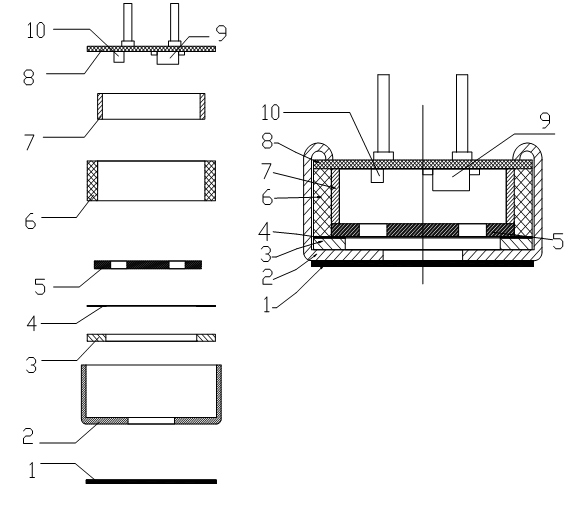

9. 材料及结构清单(List and Structure of Materials)

No. | Part name | Materials Type | Qty | Origin | Manufacture | Remarks |

1 | FELT | Fabric Cloth | 1 | China | Dongguan |

|

2 | Case | AL | 1 | China | Shanghai |

|

3 | Diaphragm | FEP50A | 1 | USA | Dupont |

|

4 | Spacer | Mylar | 1 | China | Hebei |

|

5 | Back plate | Copper Blank | 1 | China | Ningbo |

|

6 | Housping Chamber | Gather Formaldehyde | 1 | China | Changshu |

|

7 | Copper ring | Copper Tube | 1 | China | Changshu |

|

8 | P.C.B | FR-4 | 1 | China | Shuzhou |

|

9 | FET | YD100 | 1 | China | Beijing |

|

10 | Chip Capacitor | 33PF 0402 | 1 | Japan | Murata |

|